Powder Machinery

More comprehensive machine types. Meet your personalized granule and powder processing needs

EPIC Powder manufactures many machines. They are used for grinding, classifying, modifying, removing dust, drying, and spheroidizing. EPIC Powder builds these machines itself. They have high standards for controlling particle size. They also aim to increase output, reduce pollution, and have good design. The materials, output, and granularity vary based on usage scenarios. EPIC Powder provides tailored machines and processes that meet your needs better.

Products we can provide

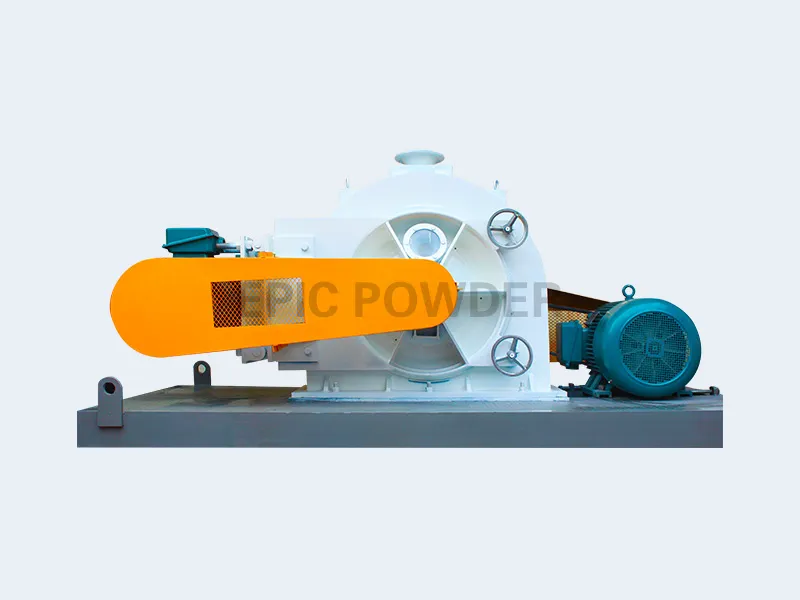

Dry Grinding

For many products in our daily lives, grinding is necessary. Grinding is key. It turns breakfast cereal, cold medicine, and paint and cement into the right shape for the market.

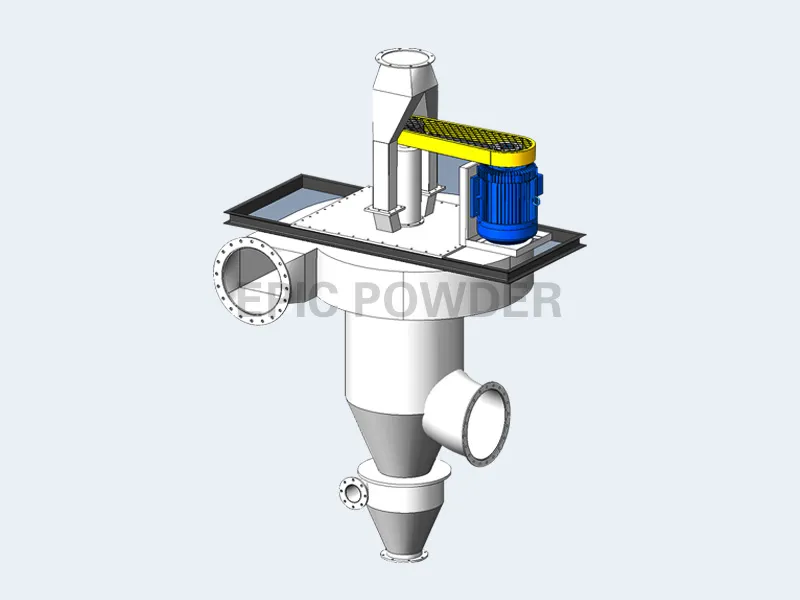

Classifying & SEPARATING

Classification are based on the effects of centrifugal force, gravity, inertial force, etc., of different sizes powders in the medium (usually air) to form different trajectories, so as to realize the separation of different sizes powders.

Powder Coating & Surface Modification

Powder surface modification has important practical significance for improving the performance of the powder, improving its practical value and opening up the development of application fields.

Drying & Dispersing

Dry milling has requirements for water content of material (usually <4%). Materials with high water content need to be properly dried before milling or reduce the moisture content to a certain limit before milling.

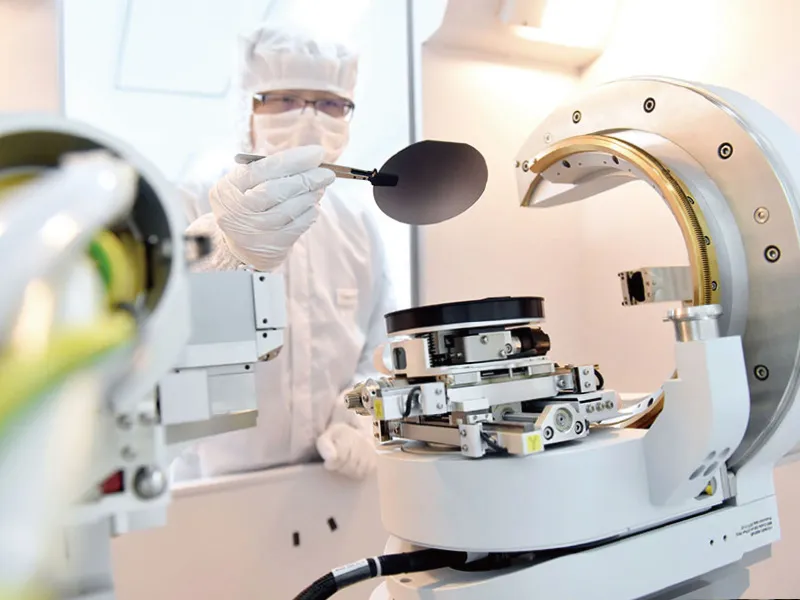

Laboratory Equipment

The material enters the airflow crusher (mechanical crusher) through an automatic feeding system and is crushed to the appropriate particle size. Different particle sizes are separated by high-speed rotating classification wheels. Qualified products are collected by a cyclone collector, and coarse particles are returned to the crushing area for further crushing.

Field of cooperation

Work with me online or in-person

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA