Ring Roller Mill

The non-metallic mineral grinding ring roller mill pulverizes non-metallic minerals into fine powder. It is designed and developed based on many years of research and experience in grinding mill production.

Working Principle

The ring roller mill uses the principles of impact, extrusion and grinding to crush materials. There are multiple layers of grinding rollers and grinding rings installed, and the material first falls between the uppermost grinding rollers and grinding rings. There is a large movable gap between the grinding roller installed on the grinding roller bracket and the pin shaft. When the material passes through the gap between the grinding roller and the grinding ring, the material will be crushed by the impact, extrusion and grinding of the grinding roller. When the material passes through the multi-layer grinding rollers and grinding rings from top to bottom, the material will be ground many times. Under the action of gravity, the crushed material falls to the bulk material tray at the bottom and is thrown to the airflow channel, and is brought into the classification area at the top by the airflow; the classifying wheel classifies the powder, and the qualified fine powder passes through the classifying wheel and enters the The dust collection system collects, and the coarse material is thrown to the inner wall of the diversion ring, and falls back into the crushing area for crushing.

Features And Benefits

- Large output, more than twice the production efficiency of Raymond mills and jet mills, good product fineness indicators, easy installation of complete sets of equipment, no large-scale civil engineering, all fine powder can be recycled, no pollution to the environment, and the dust removal effect reaches the dust industry Emission Standards;

- Widely used in calcium carbonate (calcite, marble, limestone, chalk), barite, kaolin, dolomite, magnesite, alumina, ultrafine cement, slag, steel slag and other industries;

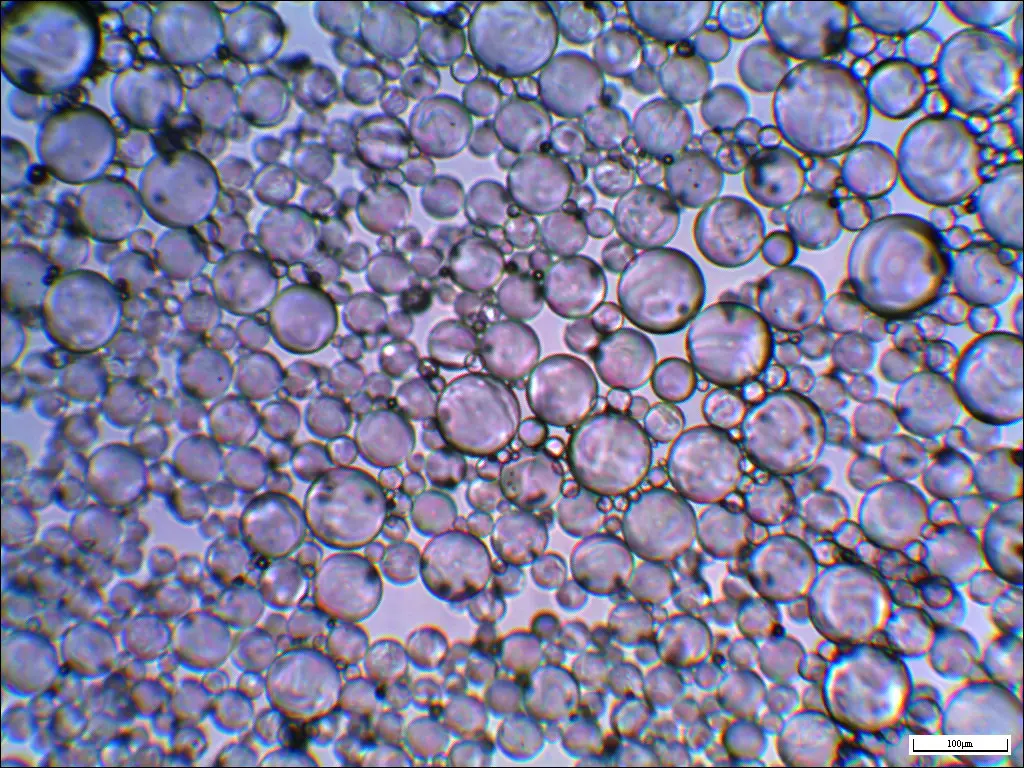

- Favorable product granularity and stability,Ideal equipment for current dry grinding method to produce non-metallic mineral fine powder such as calcium carbonate.

- Particle sizes can be adjusted as needed.Could produce powder of D97: 3-8μm, and also produce ordinary powder of D97: 10-40μm.

- Can be used in series with multi-stage classifiers to produce products with multiple sizes at one time.

- Particle size range: D50: 1.5~45μm.

Technical Parameters

| MODEL | SRM800 | SRM1000 | SRM1250 | SRM1680 |

|---|---|---|---|---|

| Feed Size (mm) | < 10 - 20 | < 10 - 20 | < 10 - 20 | < 10 - 20 |

| Moisture (%) | < 5% | < 5% | < 5% | < 5% |

| Mill Motor (kw) | 75 | 132 | 185 | 315 |

| Classifier Motor (kw) | 15 - 18.5 | 22 - 30 | 37 - 60 | 55 - 92.5 |

| Fan Motor (kw) | 37 - 45 | 55 - 75 | 75 - 110 | 132 - 180 |

| Product Fineness (mesh) | 325 - 2500 | 325 - 2500 | 325 - 2500 | 325 - 2500 |

| Production Capacity (T) | 0. 5 - 4.0 | 1.0 - 8.0 | 2.0 - 12 | 3.0 - 20 |

Project Cases

Related Posts

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA