Thee-in-One Laboratory Mill

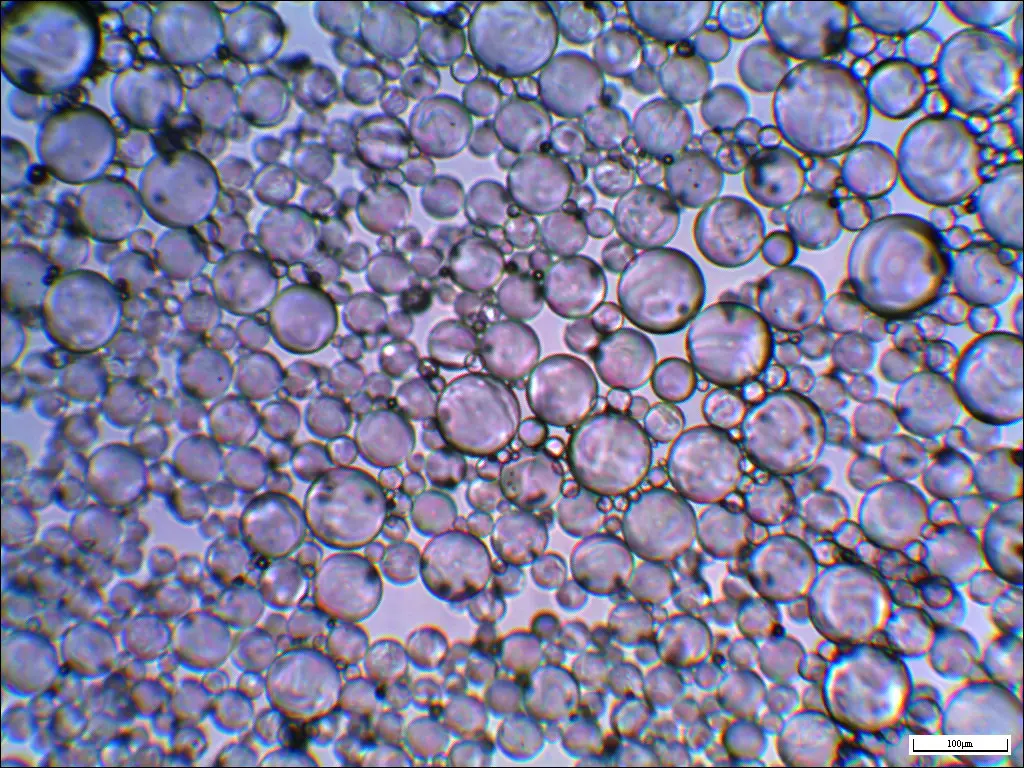

The material enters the jet mill (impact mill) through the automatic feeding system and grinds the material to a suitable particle size. The high-speed rotating classifying wheel realizes the separation of different particle sizes. The qualified products enter the cyclone collector for collection, and the coarse particles return to the grinding area. If it is necessary to classify the materials separately, combine the air classifier unit, and adjust the impeller speed through the frequency converter to achieve product classification with different particle sizes.

Working Principle

Laboratory equipment is used for the development and processing of new products, small-scale tests of high-tech products, quality control and process optimization. The main advantages of this process are flexibility, low cost, and ease of cleaning. Aiming at the need for experiments such as crushing and grading conducted by universities, research institutes, and small enterprises to research various materials, Alpine has specially developed a series of small laboratory crushing equipment. This equipment has the characteristics of small size, combined structure, mobile mechanical crusher unit, etc. It is extremely convenient to disassemble and assemble.

Features And Benefits

- Three-in-one combined structure,integrate jetmill, air classifier and impact mills.

- The equipment has compact structure, convenient operation and conversion, and small installation space.

- The key parts can be made of all-ceramic structure, zero metal pollution.

- The grinding process can be protected by inert atmosphere, which has a high safety factor.

- Especially suitable for research and development and testing of new products in scientific research institutes, college laboratories, factory research institutes, and factory laboratories.

Related Products

Project Cases

Related Posts

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA