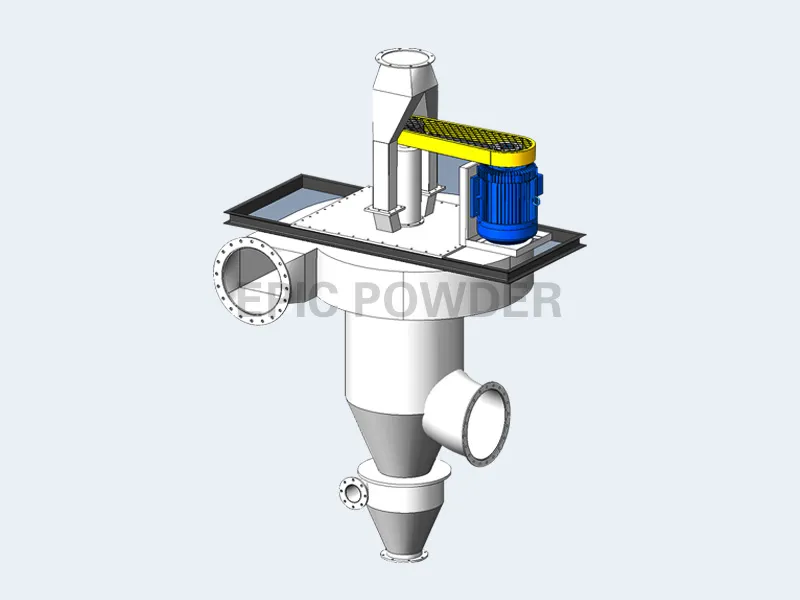

Centrifugal Classifier

CTC series air classifier is designed under the guidance of our German experts, and it is specially developed for separating powder products between 32-250μm. It does not require any peripheral equipment, such as cyclone collector, bag filter, induced draft fan, etc.

Working Principle

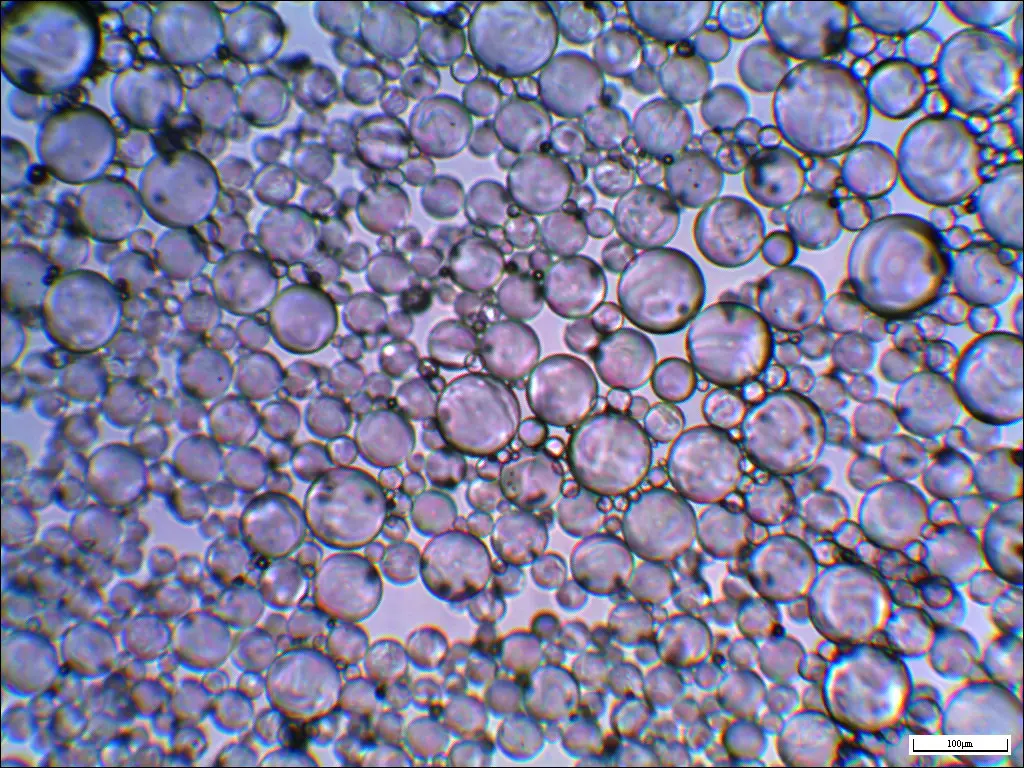

Raw material enters the classifier from the top and falls onto the rotating bulk pan. The bulk pan distributes the product in an adjustable airflow created by an internal fan. Fine particles are entrained in the airflow and carried to the outer chamber, while coarse particles fall into the inner chamber. Fine powder products and coarse powder products are discharged from the bottom of the classifier respectively. This process of internal air circulation and self-grading greatly reduces investment, production and maintenance costs. When processing high-hardness materials such as abrasives and quartz, the inlet chute and internal rotating parts can be made of high-hardness materials or lined with high hardness, depending on the situation. In addition, if it is necessary to avoid iron pollution, the interior of the classifier can be lined with alumina ceramic sheets and polyurethane.

Features And Benefits

- Classify apex top cutting:d97<32μm.

- Wide range of particle size: 32-250μm.

- The processing capacity range: 1-50t/h.

- The technology comes from Germany, and the design is mature and reliable.

- The equipment has low energy consumption, low investment cost and low maintenance cost.

- No need for peripheral equipment, small footprint.

- Suitable for abrasive, quartz sand, marble and other hard materials.

Technical Parameters

Related Products

Project Cases

Related Posts

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA