Pigments, Dyes, Printing

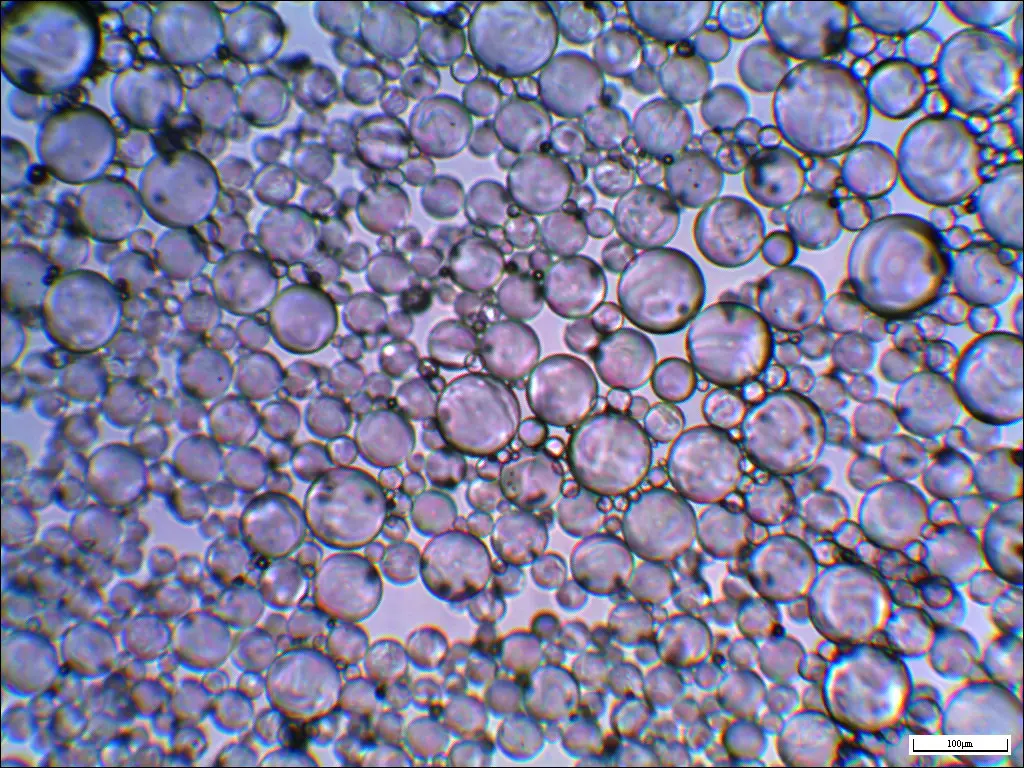

Particle size is one of the important indicators of pigments, dyes, general requirements of particle physical shape stability, particle size uniform, and good dispersion, not condensed or precipitation.

Pigments are special substances that do not dissolve in the medium, so they must be well dispersed in the medium. Because of their optical properties, they are used as coloring substances, such as in paints, printing inks or inkjet inks, or as preservatives by virtue of special technical and chemical properties.

Dyes are divided into inorganic and organic dyes. Unlike pigments, they are completely soluble in their vehicle (water or organic solvent). They can be used to color fibers (textile dyes), plastics and plastic fibers, and as color-generating substances in food technology, such as beta-carotene in soft drinks.

The ultra-fine pulverization of pigments places high requirements on the machine technology used to ensure low residue, low pollution, less impurities, and easy cleaning.

Project Cases

Related Posts

We can provide processes and equipment that meet the following performance indicators

Jet Mill

Suitable for grinding materials with high hardness, high purity and high added value.

Air Classifying Mill

Integration of grinding and classifying

Vibration Mill

High cost performance, suitable for D50:2.5~150μm grinding.

- Full ceramic protection, increased amount of metal <20ppb.

- The physical shape of the particles is stable, the particle size is uniform, and has good dispersibility, and does not cause agglomeration or precipitation.

- Simple quick disassembly and assembly structure, which is conducive to cleaning and replacing materials.

- Low residue, low pollution, less impurities.

- Jet mill can be used instead of impact mill for production, with higher safety and finer particle size.

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA