Pesticide

After the pesticide raw materials are superfinely pulverized, their uniformity, dispersion, and contact area are significantly increased, so the sterilization, insecticidal and weeding effects are significantly enhanced, and the use of pesticides is greatly reduced. In addition, the ultra-fine powder has a large specific surface area, strong adsorption capacity, and resistance to rain washing, so as to maintain the long-term effect of pesticides. Correspondingly, due to the strong surface activity of the ultra-fine powder, the decomposition rate of the agricultural and sideline products and the environment is accelerated, so the pesticide residues are reduced, and the pollution is reduced.

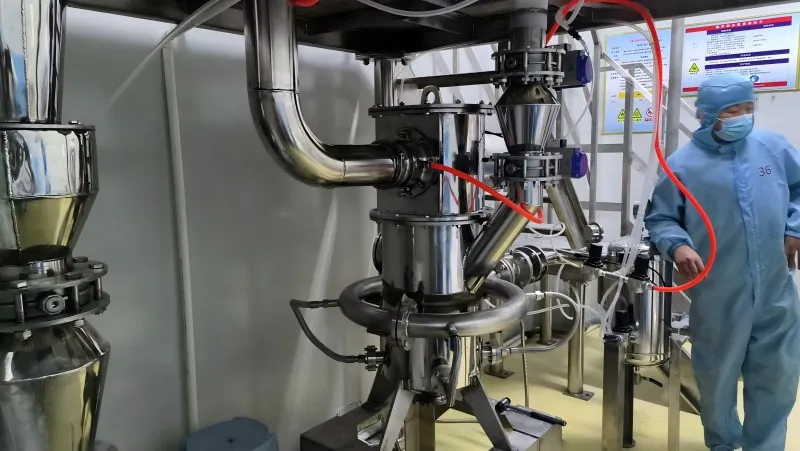

Our air classifying mill can grind pesticide raw materials to a size of 25-35 µm, while jet mills can reduce the size to 10 µm. In addition, we also provide dial grinders and hammer machines for rough grinding.

Project Cases

Related Posts

We can provide processes and equipment that meet the following performance indicators

Spiral Jet Mill

On-line cleaning (CIP) and on-line sterilization(SIP)design is optional.

Air Classifying Mill

Integration of grinding and classifying

- Quick disassembly of equipment within 10min.

- No dead angle, easy to clean.

- High produce collection efficiency 99.9%.

- Low noise design <80dB.

- On-line cleaning (CIP) and on-line sterilization(SIP)design is optional.

- Production operation protection (isolation cover/glove box).

- Process parameter storage and historical record query.

- Explosion-proof design, Full nitrogen protection.

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA