Dry Grinding

Dry milling has requirements for water content of material (usually <4%). Materials with high water content need to be properly dried before milling or reduce the moisture content to a certain limit before milling.

The powder products involved in food, medicine, fertilizer, pesticide and other industries will inevitably appear agglomeration during transportation and storage, which affects the normal use of these products and the full play of their beneficial effects. Before milling or powder surface modification, powders need to finish depolymerization.

When the material enters machine, it is milled at high speed, which increases the evaporation surface area, has a large drying capacity, significant energy saving, high thermal efficiency of more than 70%.

The quality of dried products is uniform, the maximum dehydration capacity can reach 2t/h, product modification can also be carried out at the same time.

Negative pressure, dust-free, operation is simple, maintenance cost is low, variety of automatic protection functions and high reliability.

EPIC Powder can provide dry ultrafine grinding equipmentsuitable for various materials

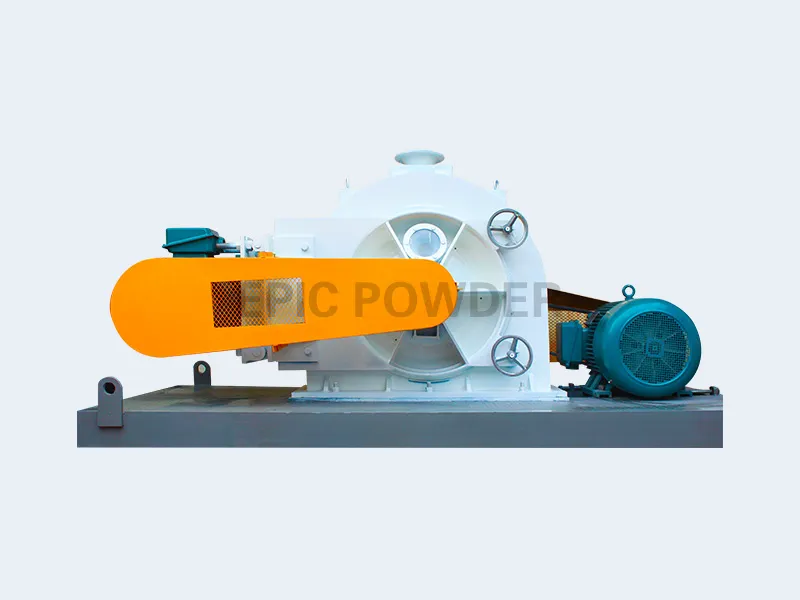

Impact mill

High eficiency, has two miling effects of impact and grind, large miling ratio, simple structure, stable operation,suitable for milling medium-soft hard materials.

Jet mill

Uses the high speed turbulence airflow generated by compressed air or superheated steam as miling power. impactextrusion, friction and shear between the particles or between the particles and the fixed plate occur, so as to achievemilling.

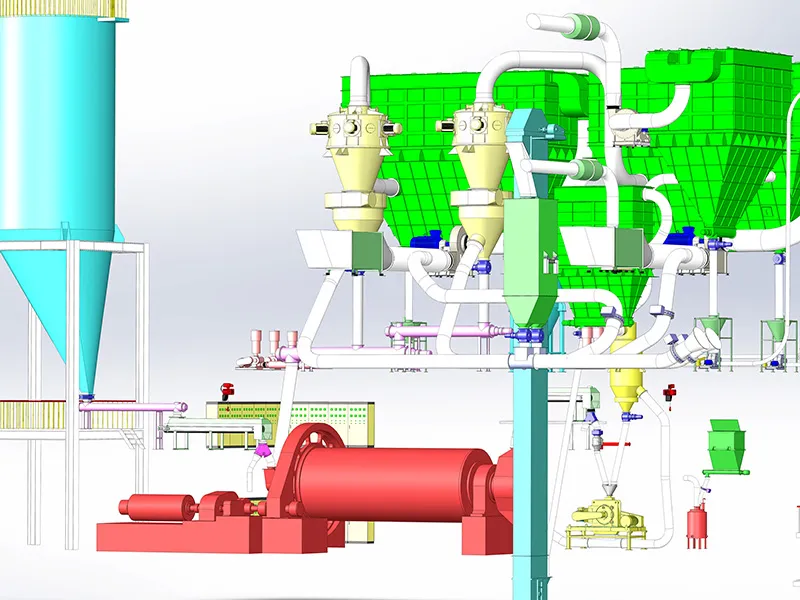

Ball mill + Classifying

The ball mill and classification production line refers to a complete set of milling system composed of Ball mil,cyclone, dust collector and fan.

Fluidized Bed Opposed Air Jet Mill

Suitable for grinding materials with high hardness, high purity and high added value.

Air Classifying Mill

Suitable for fine powders of ceramics, abrasives, glass, minerals, and polymers.

Ball Mill and Air Classifier Production Line

Cooperate with the classifier to produce products of multiple particle sizes at the same time

Pin Mill

Widely used in chemical, inorganic salt, medicine, food, pigments, materials and other industries.

Vibration Mill

A vibration mill is a size reduction equipment that applies the process of continuous impaction

Industry we serve

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA