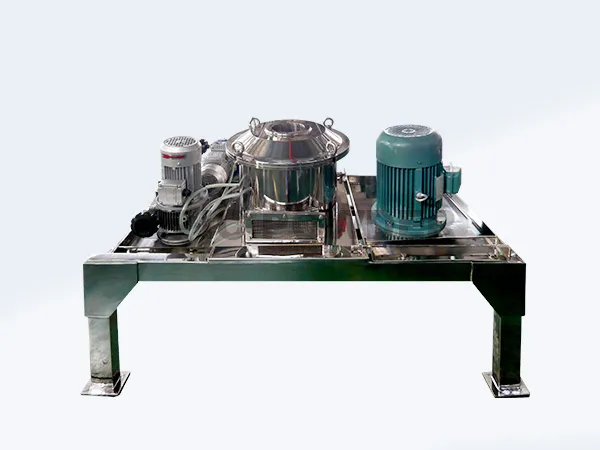

Impact Mill

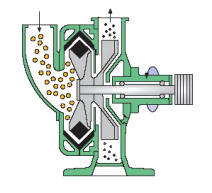

The material is evenly fed into the grinding chamber by the feeding system, and is strongly impacted by the high-speed rotating crushing disc, and at the same time, it is subjected to various forces such as friction, shearing, and collision between the static disk and the ring gear, and is finally crushed.

Working Principle

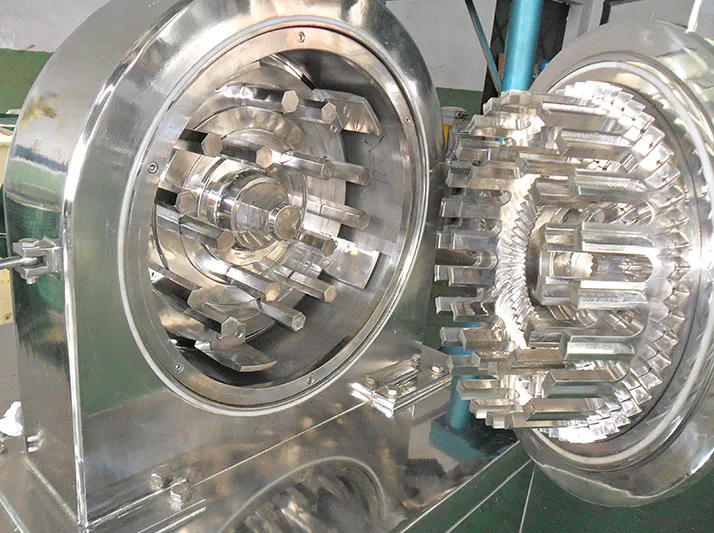

The material is evenly fed into the grinding chamber by the feeding system, and is strongly impacted by the high-speed rotating crushing disc, and at the same time, it is subjected to various forces such as friction, shearing, and collision between the static disk and the ring gear, and is finally crushed. The crushing movable disk and static disk can be combined in different structures to meet the crushing requirements of different materials. The structural forms we currently design include: hammer type, pin type, turbine type, and grinding disc type.

Features And Benefits

- Hammer type is suitable for pre-crushing and coarse crushing.

- The pin type is suitable for brittle, viscous and heat-sensitive materials.

- Turbine type is suitable for brittle materials and fibrous materials.

- The grinding disc type is suitable for tough and elastic materials,such as plastics.

- Hammer type and turbine type generally have a built-in screen to control the fineness of the product.

- Explosion-proof design can meet the crushing requirements of flammable, explosive and oxidizable materials.

- Low temperature design can meet the crushing requirements of heat sensitive materials.

Technical Parameters

| Type | Model | 160 | 250 | 360 | 500 | 630 | 800 |

|---|---|---|---|---|---|---|---|

| Blast mill MJL-B | Speed (r/min) | 12000 | 7500 | 5550 | 3850 | 3200 | 2800 |

| Power(kW) | 4 | 5.5-7.5 | *11-15 | 18.5-30 | 30-45 | 37-75 | |

| Fineness(mesh) | 20-325 | ||||||

| Hammer mill MJL-H | Speed (r/min) | 9000 | 6000 | 4680 | 2480 | 2300 | 2150 |

| Power(kW) | 4 | 7.5 | 22 | 37 | 22-45 | 55 | |

| Fineness(mesh) | 20-325 | ||||||

| Disc mill MJL-D | Speed (r/min) | 12000 | 7500 | 5550 | 3850 | 3200 | 2800 |

| Power(kW) | -- | -- | 15 | 30 | 45 | 8 | |

| Fineness(mesh) | 20-325 | ||||||

Related Products

Project Cases

Related Posts

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA

| MODEL | MQW03 | MQW06 | MQW10 | MQW20 | MQW30 | MQW40 | MQW60 | MQW80 | MQW120 | MQW160 | MQW240 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Feeding Size(mm) | <1 | <2 | <2 | <3 | <3 | <3 | <3 | <3 | <3 | <3 | <3 |

| Production Capacity(kg/h) | 0.3~10 | 10~150 | 20~300 | 40~600 | 100~900 | 200~1200 | 500~2000 | 800~3000 | 1500~6000 | 2000~8000 | 4000~12000 |

| Particle size(D97:μm) | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 | 3~45 |

| Classifier motor (kw) | 2.2 | 3 | 5.5/7.5 | 7.5/11 | 11/15 | 15/7.5x3 | 7.5x3 | 11x3 | 15x3 | 15x4 | 15x6 |

| Air consumption(m³/min) | 3 | 6 | 10 | 20 | 30 | 40 | 60 | 80 | 120 | 160 | 240 |

| Air pressure(Mpa) | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 | 0.6~1 |