Drying & Dispersing

For many products in our daily life requires grinding process. From breakfast cereals to cold medicine to paint and cement, grinding is a key step in bringing products to the market in the right form.

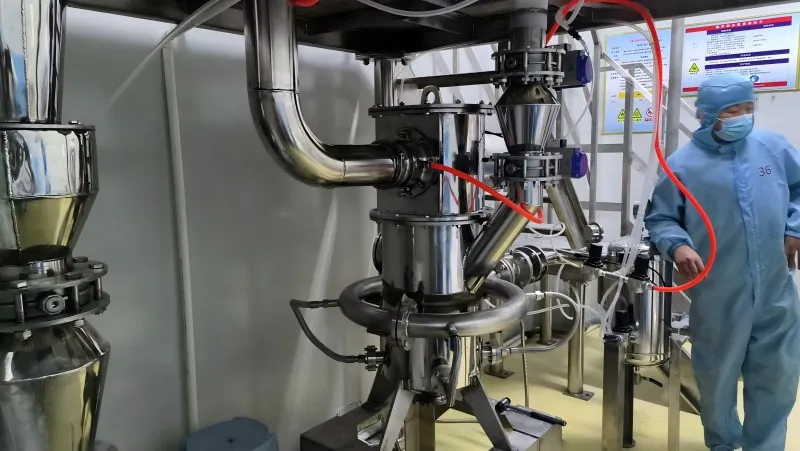

When the material enters machine, it is milled at high speed, which increases the evaporation surface area, has a large drying capacity, significant energy saving, high thermal efficiency of more than 70%.

The quality of dried products is uniform, the maximum dehydration capacity can reach 2t/h, product modification can also be carried out at the same time.

Negative pressure, dust-free, operation is simple, maintenance cost is low, variety of automatic protection functions and high reliability.

Rotor Mill for drying, dispersing and modifying

Realize the functions of drying, dispersing and modifying at the same time

Industry we serve

Send Us A Message

PHONE

+86 15762272120 Mon to Fri 08:00 am – 6:00 pm

LOCATION

NO. 369, Road S209, Huanxiu, Qingdao City, 266201, Shandong Province, CHINA