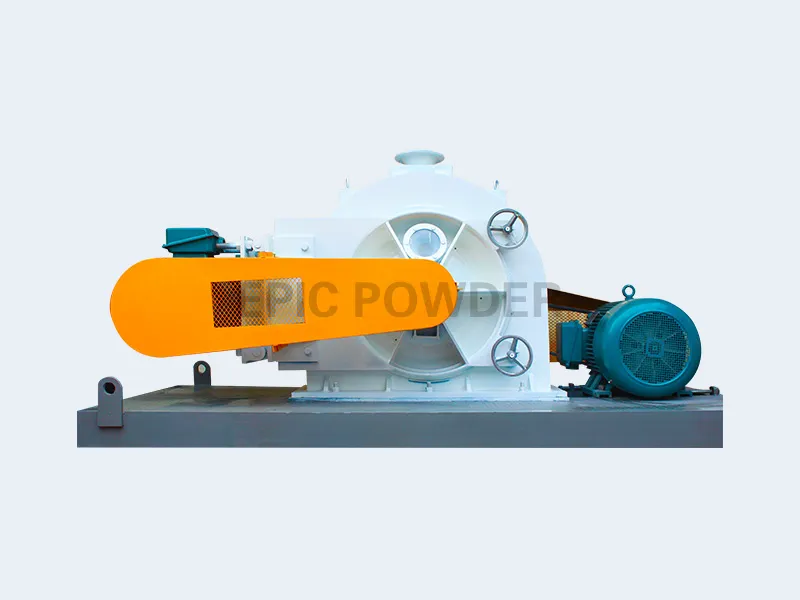

Mesin Pelapis Pin Mill

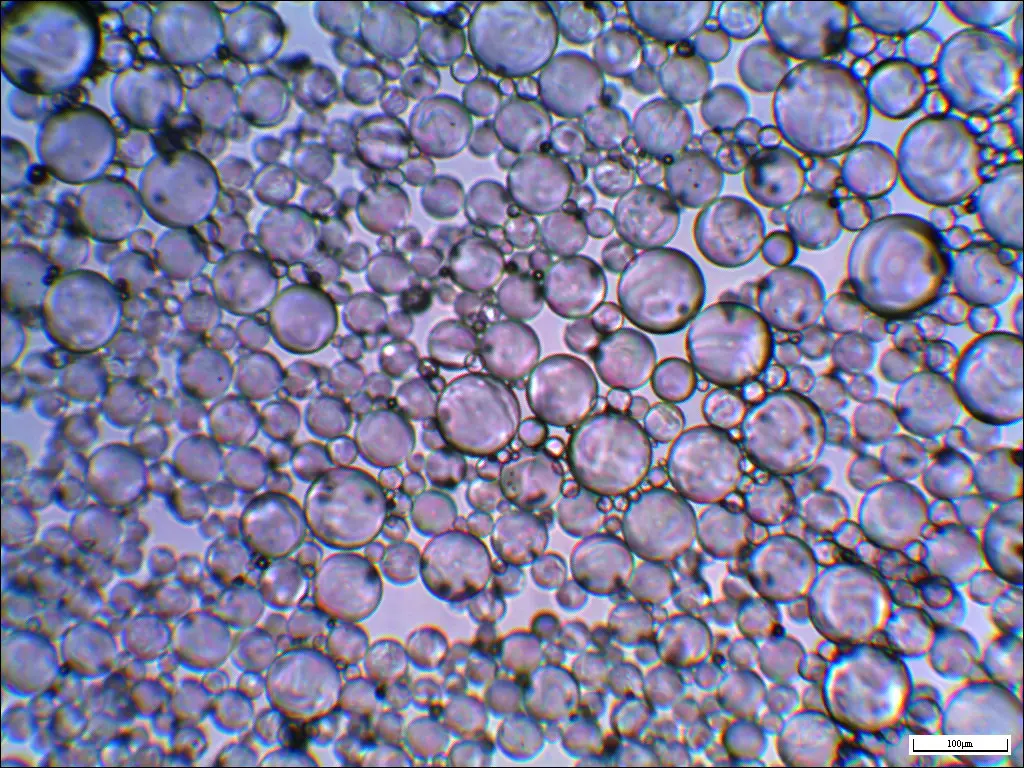

The EPIC’s proprietary injector design achieves a high degree of atomization of the coating fluid, while the high tip speeds produced by the counter-rotating pin disks provide the high shear forces required for proper dispersion and uniform coating. Each coating system is custom designed for the application and includes all auxiliary equipment. Because of its unmatched efficiency, the Pin mill for the Calcium carbonate coating system consumes less power and fluid than any other method in use today.

- This machine provides continuous coating process.

- This type of machine is very popular in European and American markets.

- Two motors run in opposite direction. The linear speed can be up to 240m/s.

- High speed impact, shear and friction leads to full dispersion of materials and due to it, temperature of the material rises resulting in powder modification completely.

Prinsip Kerja

The pin mill is a fine impact mill with two driven pin discs. In counter-rotating mode, much higher relative speeds are possible than with the ACM fine impact mill with only one driven pin disc. The highest relative speed develops at the outermost pin rows and can be up to 240 m/s.

The fineness can be adjusted by altering the pin disc speeds. The centrifugal forces acting on both discs ensure that even moist, greasy and sticky products can be processed. The design with the wide-chamber housing is ideal for processing these kinds of products. The feed material is often embrittled by intensive mixing with liquid nitrogen.

The mill door can be hinged opened wide to permit easy cleaning.

Parameter Teknis

| Model | PM400C | PM630C | PM800C |

|---|---|---|---|

| Standard drive (kW) | 30 + 37 | 55 + 55 | 110 + 110 |

| Fineness (μm) | 3 – 75 | 3 – 75 | 3 – 75 |

| Capacity (t/h) | 1 – 5 | 2 – 10 | 4 – 20 |

Produk Terkait

Kasus Proyek

Posting Terkait

Kirimkan Kami Pesan

TELEPON

+86 15762272120 Senin sampai Jumat 08:00 – 18:00

LOKASI

TIDAK. 369, Jalan S209, Huanxiu, Kota Qingdao, 266201, Provinsi Shandong, CHINA