Klasifikasi Udara

Pengklasifikasi udara ideal untuk serbuk halus keramik, bahan abrasif, kaca, mineral, dan polimer. Jika Anda tidak yakin apakah umpan khusus Anda cocok atau tidak, berikut beberapa sifat material yang perlu dipertimbangkan.

Kandidat yang baik:

Bahan padat

Bahan keras

Bahan bulat/bulat

Bahan yang mengalir bebas

Bahan yang terdispersi dengan baik di udara

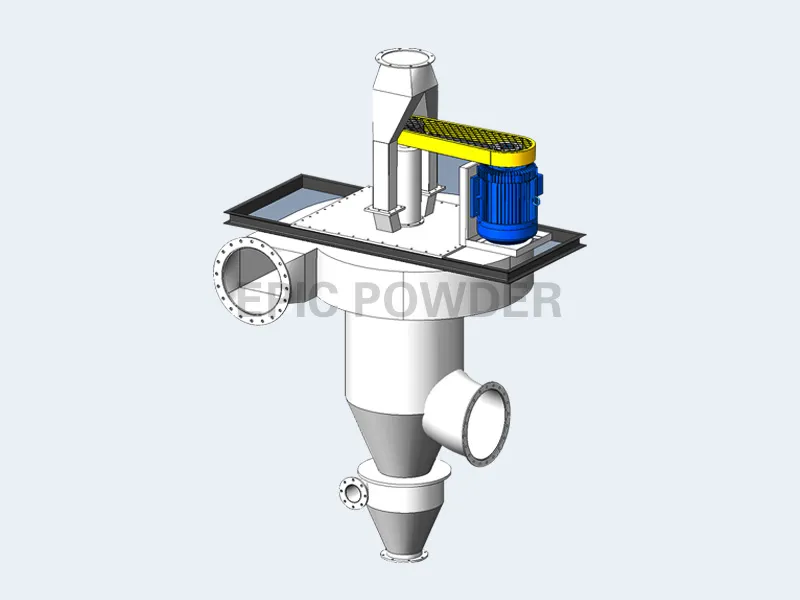

Prinsip Kerja

Di bawah aksi kipas, material bergerak ke area klasifikasi dengan kecepatan tinggi dari saluran masuk bawah pengklasifikasi dengan arus naik. Di bawah aksi gaya sentrifugal kuat yang dihasilkan oleh turbin klasifikasi berputar berkecepatan tinggi, material dipisahkan, dan partikel halus yang memenuhi persyaratan ukuran partikel memasuki pemisah siklon atau pengumpul debu melalui celah bilah roda klasifikasi untuk dikumpulkan. Kecepatan beberapa partikel halus yang terbawa oleh partikel kasar menghilang setelah menabrak dinding, dan kemudian berkurang ke saluran keluar udara sekunder di sepanjang dinding silinder. Melalui efek pencucian yang kuat dari udara sekunder, partikel kasar dan halus dipisahkan, partikel halus naik ke klasifikasi sekunder di area klasifikasi, dan partikel kasar turun ke port pembuangan untuk dibuang.

Fitur dan Manfaat

Pengklasifikasi Udara adalah proses pemisahan partikel halus dengan memanfaatkan gaya sentrifugal dan hambatan aerodinamis yang berlawanan. Pengklasifikasi udara dapat memilah partikel berdasarkan massa secara tepat, dapat diprediksi, dan efisien, sehingga menghasilkan fraksi partikel kasar dan fraksi partikel halus.

- Berbagai rotor klasifikasi tersedia, dan output dapat disesuaikan; kecepatan roda dikontrol oleh inverter, ukuran partikel dapat disesuaikan secara bebas. Roda klasifikasi dapat dibuat dari bahan keramik, tanpa polusi logam, memenuhi persyaratan bahan dengan kemurnian tinggi.

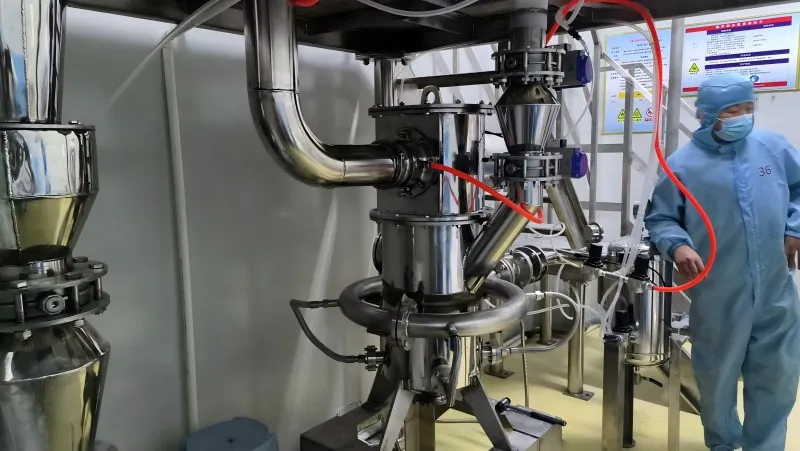

- Penggilingan dilakukan dalam sistem tertutup, sedikit debu, kebisingan rendah dalam proses yang bersih dan ramah lingkungan.

- Dikombinasikan dengan ball mill, table roller mill dan Raymond mill untuk membentuk sirkulasi tertutup.

- Desain anti-ledakan opsional, juga dapat ditingkatkan ke sistem sirkulasi nitrogen untuk memenuhi kebutuhan pemrosesan bahan oksida yang mudah terbakar dan meledak.

Parameter Teknis

Produk Terkait

Kasus Proyek

Posting Terkait

Kirimkan Kami Pesan

TELEPON

+86 15762272120 Senin sampai Jumat 08:00 – 18:00

LOKASI

TIDAK. 369, Jalan S209, Huanxiu, Kota Qingdao, 266201, Provinsi Shandong, CHINA