Sistem Produksi Ball Mill dan Pengklasifikasi Udara

Bekerja sama dengan pengklasifikasi untuk memproduksi produk dengan berbagai ukuran partikel pada saat yang sama. Kapasitas produksi dan kisaran ukuran partikel akan berbeda-beda, tergantung pada bahan dan industri aplikasi yang berbeda.

Prinsip Kerja

Setelah penghancuran kasar, material dimasukkan ke dalam ball mill melalui perangkat pengumpanan yang dapat dikontrol. Media penggilingan di dalam mill berulang kali menghantam dan menggiling material berdasarkan energi kinetik yang diperoleh saat mill berputar. Material yang dihancurkan dibuang ke dalam tangki isap melalui ekor ball mill, lalu diangkut ke pengklasifikasi untuk diklasifikasi dengan tekanan negatif. Serbuk halus yang memenuhi syarat dikumpulkan oleh pengumpul siklon atau pengumpul debu. Partikel kasar setelah diklasifikasi dibuang dari ujung bawah pengklasifikasi, lalu masuk kembali ke ball mill untuk dihancurkan melalui pipa pengumpanan.

Sistem Produksi Ball Mill dan Pengklasifikasi Udara

Penggiling bola

Desainnya berbeda dari pabrik semen tradisional dan pabrik pertambangan dan metalurgi, dan memenuhi persyaratan pemrosesan mineral kelas pengisi superhalus Jerman. Optimalkan rasio aspek untuk mencegah penggilingan berlebihan dan mencapai hasil penggilingan yang optimal. Optimalkan rasio pembukaan dan desain pembukaan rahang, dan tingkatkan kehalusan penggilingan dengan media penggilingan yang lebih kecil. Ekor penggilingan tipe pelat mengeluarkan, pembuangannya halus, tidak ada fenomena penggilingan, dan silinder tidak perlu didinginkan. Media penggilingan sesuai dengan persyaratan produk, rasio yang wajar, laju pengisian tinggi, efisiensi tinggi. Alat bantu penggilingan saat menggiling bubuk sangat halus untuk meningkatkan efisiensi penggilingan. Optimalkan pencocokan energi penggerak dan penggilingan untuk memaksimalkan penghematan energi. Dan pengklasifikasi membentuk sistem tertutup, pengangkutan tekanan negatif, tidak ada debu. Optimalkan bentuk dan bahan lapisan dan media penggilingan, sesuai dengan standar Jerman, kurangi tingkat kerusakan dan tingkatkan efisiensi penggilingan. Mineral keras dapat dirancang tanpa polusi besi, dan lapisan dan badan penggilingan terbuat dari keramik alumina, kuarsa, SILEX atau bahan khusus.

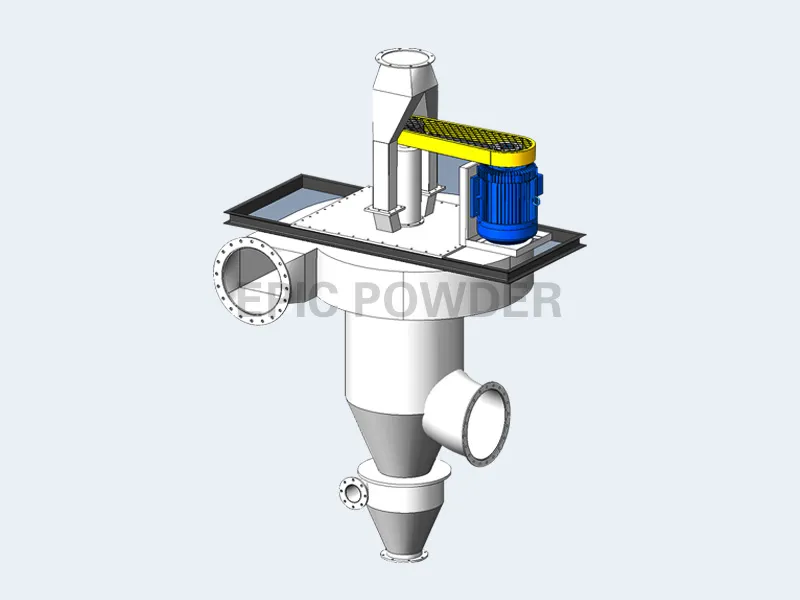

Penggolong

Berbagai model Classifier dapat dipilih tergantung pada kehalusan produk yang berbeda. Classifier seri HTS cocok untuk mengklasifikasikan produk D97:3~20μm, seri ITC untuk mengklasifikasikan produk D97: 8~45μm. Berbagai macam penyesuaian tersedia dengan setiap Classifier dan aplikasinya luas di pasaran. Dengan menggunakan berbagai kombinasi classifier tunggal atau ganda, produk dengan kehalusan yang berbeda dapat diproduksi pada saat yang sama, atau spesifikasi produk dapat diubah kapan saja sesuai dengan permintaan, yang memiliki fleksibilitas yang lebih besar. Classifier dilengkapi dengan sensor kecepatan dan sistem kontrol untuk mengukur, mengevaluasi, dan mengompensasi suhu udara, tekanan udara, volume udara, dan perbedaan tekanan filter, sehingga dapat memastikan stabilitas kualitas produk.

Parameter Teknis

| MODEL | 1530 | 1557 | 1850 | 1870 | 2250 | 2270 | 2450 | 2470 | 2660 | 2670 | 3070 | 3090 | 3280 | 3290 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Diameter silinder (m) | 1.5 | 1.5 | 1.83 | 1.83 | 2.2 | 2.2 | 2.4 | 2.4 | 2.6 | 2.6 | 3 | 3 | 3.2 | 3.2 |

| Panjang silinder (m) | 3 | 5.7 | 5 | 7 | 5 | 7 | 5 | 7 | 6 | 7 | 7 | 9 | 8 | 9 |

| Daya motor (kw) | 75 | 132 | 160 | 250 | 250 | 380 | 320 | 475 | 500 | 630 | 800 | 1000 | 1250 | 1400 |

| Ukuran pemberian pakan (mm) | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 | 1 ~ 5 |

| Kehalusan (um) | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 | 5 - 75 |

Produk Terkait

Kasus Proyek

Posting Terkait

Kirimkan Kami Pesan

TELEPON

+86 15762272120 Senin sampai Jumat 08:00 – 18:00

LOKASI

TIDAK. 369, Jalan S209, Huanxiu, Kota Qingdao, 266201, Provinsi Shandong, CHINA