Honeycomb grinding - drying, depolymerization, modification, modification

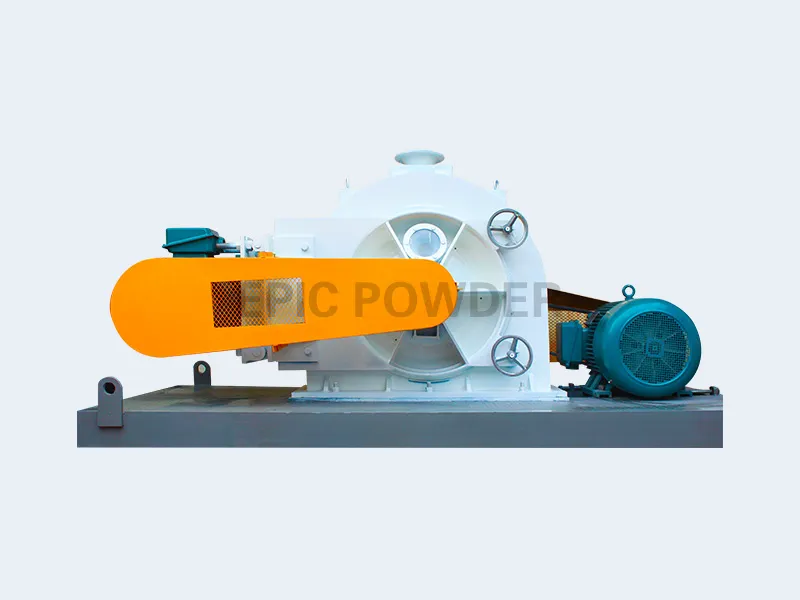

- Honeycomb mill is a mechanical grinding machine that advocates the practical process of first depolymerization and then drying, and synchronous surface treatment. It is specifically designed for the production of ultrafine powders with strict requirements for particle size distribution.

- Simultaneously achieve grinding, drying, sorting, and surface chemical treatment with powder, while drying and depolymerizing wet grinding filter cake and slurry.

- The minimum processing capacity is 0.05 tons/hour, the maximum is 15 tons/hour, and the maximum water evaporation capacity is 3 tons/hour.

- According to the diversity of materials, different materials can be used inside the equipment, which have the advantages of retaining the color and purity of the materials. The coating rate can reach 99.2%, and the activation rate can reach 99.8%.

작동 원리

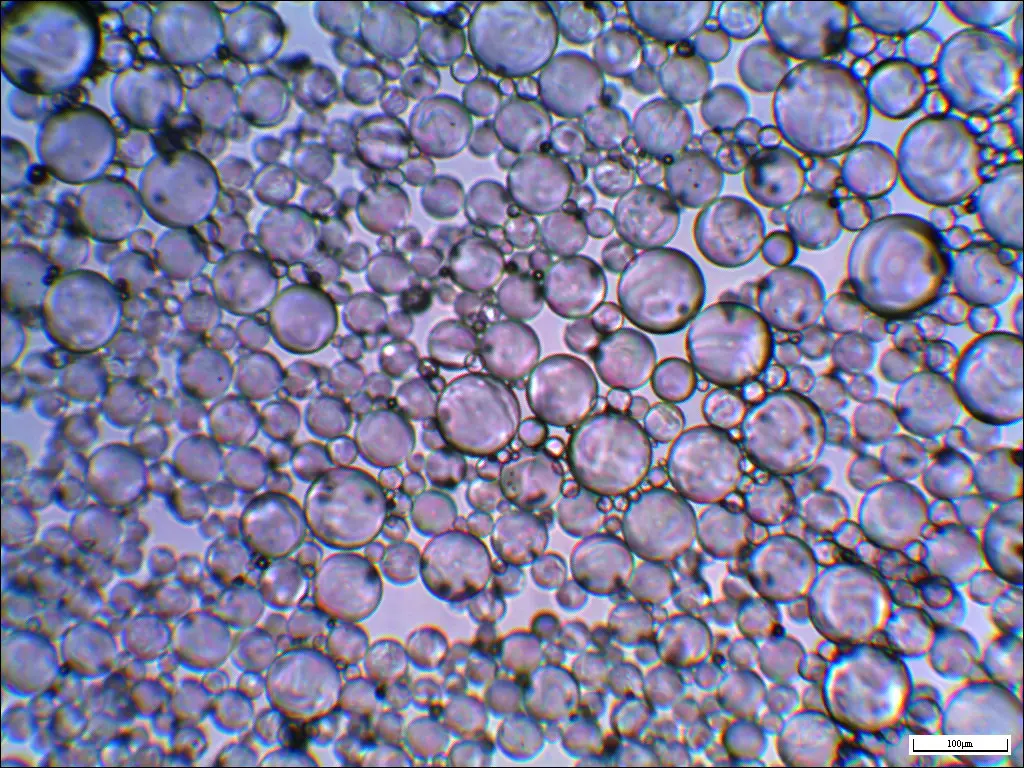

The main component is a vertically installed multi-stage disassembly wheel, each stage of disassembly wheel consisting of two supporting discs mounted on the main shaft and clamping 200 blades. According to specific load requirements, a honeycomb mill can install 10 disassembly wheel components and a maximum of 2000 disassembly blades. The blades rotate at a speed of 110 meters per second, and the grinding groove of 6 millimeters is a unique reinforcing rib type fixed lining. 160 turbulent “honeycombs” are formed between the blades and the lining, and the pressure, shear force, and friction between them can quickly grind the material into ultrafine powder.

Characteristics of Honeycomb Grinding

All honeycomb mills are designed with modularity. This allows for the adoption of optimal designs for different environments for each device, while maintaining the basic principles and identical components unchanged.

Optimize equipment performance by changing the number of rotor layers and blades. The integrated installation of the sorting machine does not affect the structure of the main grinding chamber.

This modular structural design makes maintenance and replacement of vulnerable parts very easy.

The material of rotor blades can be hardened steel, stainless steel, or tungsten carbide steel.

The grinding groove material is made of steel, high chromium iron, stainless steel, or high alumina ceramics.

Honeycomb grinding characteristics

The rotor and lining strip can be removed as a whole from the mill.

The rotor and lining can be repaired outside the mill, reducing downtime.

The rotating components use drive pins instead of keys, making installation easier.

There are no blades or lining bolts inside the grinder.

The rotating components underwent dynamic balancing inspection before installation to ensure the service life of the bearings.

During normal operation, there is no need to make any adjustments to the honeycomb mill.

Characteristics of Honeycomb Grinding

All honeycomb mills are designed with modularity. This allows for the adoption of optimal designs for different environments for each device, while maintaining the basic principles and identical components unchanged.

Optimize equipment performance by changing the number of rotor layers and blades. The integrated installation of the sorting machine does not affect the structure of the main grinding chamber.

This modular structural design makes maintenance and replacement of vulnerable parts very easy.

The material of rotor blades can be hardened steel, stainless steel, or tungsten carbide steel.

The grinding groove material is made of steel, high chromium iron, stainless steel, or high alumina ceramics.

Honeycomb grinding characteristics

The rotor and lining strip can be removed as a whole from the mill.

The rotor and lining can be repaired outside the mill, reducing downtime.

The rotating components use drive pins instead of keys, making installation easier.

There are no blades or lining bolts inside the grinder.

The rotating components underwent dynamic balancing inspection before installation to ensure the service life of the bearings.

During normal operation, there is no need to make any adjustments to the honeycomb mill.

Honeycomb grinding and drying function

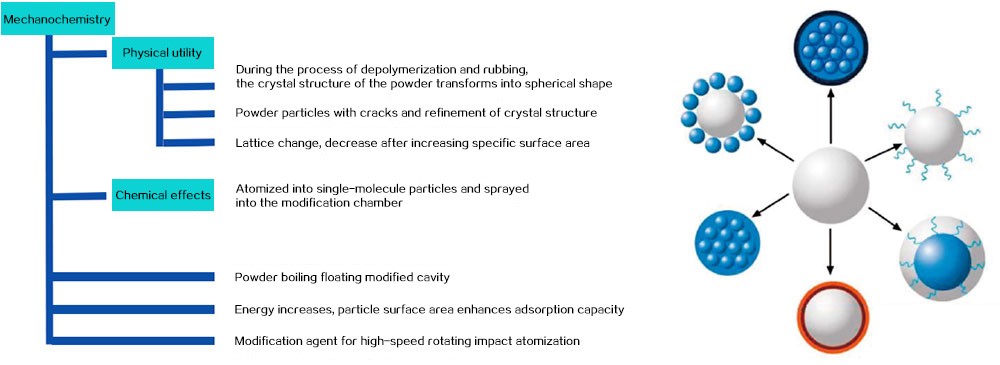

Functional materials often require surface treatment to alter their functionality. The vast majority of surfactants can be injected into the grinding zone of the mill after being measured in a certain proportion. Under normal conditions, two or more coating media can be applied simultaneously.

기술적 매개변수

| 모델 | MRD-1 | MRD-2 | MRD-3 | MRD-4 | MRD-5 | MRD-6 |

|---|---|---|---|---|---|---|

| Grinding Motor Power(kW) | 45 | 90 | 160 | 200 | 315 | 450 |

| Classifying Motor Power (kW) | 5.5 | 7.5 | 15 | 22 | 37 | 55 |

| Blade(layer) | 3-6 | 4-7 | 5-8 | 5-8 | 5-8 | 6-10 |

| Blade speed(m/s) | 120 | 120 | 120 | 120 | 120 | 120 |

| Air volume(m³/h) | 4,500 | 7,000 | 12,000 | 16,000 | 24000 | 36,000 |

관련 상품

메시지를 보내주세요

핸드폰

+86 15762272120 월~금 08:00 am – 6:00 pm

위치

아니요. 중국 산동성 266201 칭다오시 환시우 S209로 369호