The size of particles is called “grain size” .It is also known as “particle size” or “diameter.” When a particle’s physical behavior matches that of a sphere, the sphere’s diameter is called the equivalent grain size. This applies when comparing physical properties or behaviors. For non-spherical particles, the size depends on measurement methods. In such cases, particle size is only “equivalent.” It varies with the measuring standard and statistics used. Powder particle size is one of the important parameters to measure material performance, which directly affects its fluidity, dispersibility and reactivity. Ultrafine grinding machine can refine particles to micrometer or even nanometer level, meeting the strict requirements of high-end applications on particle size.

The percentage (or cumulative percentage) of particles with different particle size intervals in the total amount of powder is called frequency particle size distribution (or cumulative particle size distribution). Its ordinate is the particle size composition calculated by different standards, which can be the percentage or cumulative percentage of number, length, area, volume. Its abscissa is the particle size value calculated by different standards. D10, D50, and D90 can reflect the uniformity of the powder, which is also called the cumulative distribution of the powder.

D50

D50, also called median particle size, refers to the particle size at 50% cumulative distribution. It represents a typical value of particle size in the sample. It divides the sample into two equal parts by quantity. 50% of particles are larger than this size, 50% are smaller. If D50 = 5 μm, half of the particles are larger than 5 μm. The other half of the particles are smaller than 5 μm. D50 is commonly used to represent the average particle size.

D90

D90 refers to the particle size at 90% cumulative distribution. It means 90% of particles are smaller than this size. D90 represents the coarse-end size of the powder. It is a key indicator in powder production and use. Some industries use D95 or D97 as alternatives. Their physical meaning is similar to that of D90.

D10

D10 refers to the particle size at 10% cumulative distribution. It means 10% of particles are smaller than this size. It is the opposite of D90 in particle size distribution. D10, D50, and D90 are important in many applications. In pharmaceuticals, they relate to drug effectiveness and side effects. In environmental fields, they help monitor air and water quality.

Selection of powder equipment and particle size control

To obtain the ideal particle size distribution, it is necessary to select suitable ultrafine grinding machine and finely control its parameters:

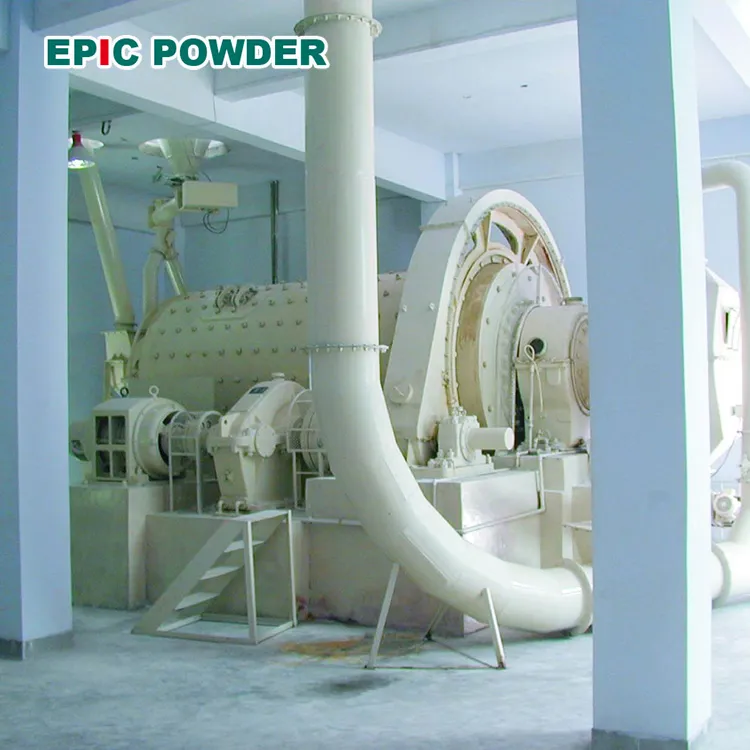

Mechanical mill (ball mill, roller mill, etc.)

- Applicable to medium-hard and high-toughness materials.

- The particle size can be controlled by adjusting parameters such as ball diameter, ball-to-material ratio, rotation speed, time, etc.

- Advantages: mature equipment and wide range of applications.

- Precautions: Over-grinding may lead to uneven particle size, increased specific surface area, and damage to material structure.

- Case: A cement plant increased the ball mill speed from 60% to 72% of the critical speed. The clinker D50 was reduced from 45μm to 32μm. The specific surface area increased by 15%, and the early strength compliance rate increased by 20%.

Air jet mill

Suitable for materials with high requirements for particle size control and temperature sensitivity, such as graphite, metal oxides, etc.

- Relying on the shear and collision energy generated by high-speed airflow to achieve ultra-fine grinding.

- Parameter control: air pressure, flow rate, feed amount, classification wheel speed.

- Advantages: product particle size is controllable, powder is clean, no metal pollution.

- Case: A graphite anode material company increased the classifier wheel speed from 4500rpm to 6000rpm. The intake pressure was stabilized at 0.8MPa, and D90 was stabilized from 18±3μm to 15±0.5μm. The battery rate performance was improved by 12%.

Classification equipment (air classifier, cyclone classifier)

- Used in combination with crushing equipment to achieve fine sorting of particle size.

- Can achieve accurate classification based on the movement trajectory and mass of particles.

- Commonly used for D50 and D90 regulation to meet different downstream application requirements.

conclusion

As the powder industry advances toward refinement and functionality, controlling particle size distribution becomes a core technology for tuning material properties. Scientific selection of ultrafine grinding machine and well-designed grinding and classification processes are key to ensuring product quality and enhancing competitiveness. In the future, with smart manufacturing and automation on the rise, the coordinated optimization of particle size distribution and powder equipment will drive the materials industry to higher levels.

Epic powder

Epic Powder, 20+ years of work experience in the ultrafine powder industry. Actively promote the future development of ultra-fine powder, focusing on crushing,grinding,classifying and modification process of ultra-fine powder. Contact us for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert !