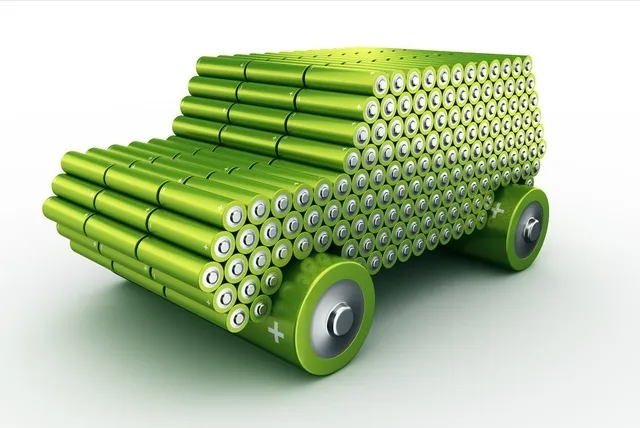

Ultrafine pulverizer, as advanced grinding equipment, play a significant role in the processing of various materials, including Lithium Iron Phosphate (LiFePO₄). LiFePO₄ is a key material used in lithium-ion batteries, particularly for energy storage applications. This article explores the integration of ultrafine pulverizer technology in the production of LiFePO₄, examining the benefits, challenges, and future prospects of this combination.

Ultrafine Pulverizer Technology Overview

An ultrafine pulverizer is a device used for grinding and refining materials into extremely fine powders. The technology operates by applying high shear forces, impact, and friction to break down larger particles into sub-micron sizes.

Ultrafine pulverizers are widely used in industries such as chemicals, pharmaceuticals, and materials processing. The technology provides precise control over particle size and uniformity, enhancing material properties. Key types of ultrafine grinding equipment include jet mills, ball mills, and roller mills. Ongoing advancements in this field aim to improve efficiency, reduce energy consumption, and increase the grinding precision of the equipment.

Characteristics and Applications of Lithium Iron Phosphate

Lithium Iron Phosphate (LiFePO₄) is a highly stable and safe cathode material for lithium-ion batteries. Its chemical structure allows it to offer excellent thermal stability, high cycle life, and enhanced safety compared to other cathode materials.

LiFePO₄ is commonly used in applications such as electric vehicles (EVs), stationary energy storage systems, and portable electronics. Its advantages over traditional lithium cobalt oxide (LiCoO₂) include lower cost, improved safety, and a more eco-friendly profile. However, its relatively low conductivity has limited its wider adoption in high-performance applications.

Application of Ultrafine Pulverizer in LiFePO₄ Processing

Using ultrafine pulverizer technology to process LiFePO₄ offers several advantages in improving its material properties.

Firstly, ultrafine grinding can reduce the particle size of LiFePO₄, leading to better dispersion in battery electrodes. Smaller, more uniform particles also enhance the material’s surface area, improving the conductivity and overall performance of the battery.

Using ultrafine pulverizer technology to process LiFePO₄ offers several advantages in improving its material properties. Firstly, ultrafine grinding can reduce the particle size of LiFePO₄, leading to better dispersion in battery electrodes.

Smaller, more uniform particles also enhance the material’s surface area, improving the conductivity and overall performance of the battery.

Additionally, ultrafine pulverizing allows for precise control of particle size distribution, which is essential for ensuring consistent and reliable performance in battery applications. A more homogeneous particle size helps achieve better packing density in the electrode, resulting in increased energy density and faster charge/discharge rates.

Furthermore, the mechanical activation provided by ultrafine pulverization can improve the electrochemical properties of LiFePO₄, making it more efficient in energy storage systems.

Advantages and Challenges of Ultrafine Pulverizer Technology

Ultrafine pulverizer technology offers many advantages for LiFePO₄ processing. It provides an efficient, low-cost method for obtaining high-quality, fine powders. These fine powders are essential for improving battery performance.

The ability to control particle size with high precision enhances the material’s properties. This contributes to the overall efficiency of energy storage systems.

However, challenges remain in the powdering process. One issue is the high energy consumption during ultrafine grinding, especially when processing hard materials like LiFePO₄.

Another challenge is the potential for contamination during grinding. Contamination could affect the purity and performance of the material.

Environmental concerns must also be addressed. Dust generation and waste disposal are key issues during the pulverizing process. These need to be managed to make the technology more sustainable.

Future Outlook and Technological Innovation

The integration of ultrafine pulverizer technology in LiFePO₄ production is expected to evolve. Research and development efforts will focus on improving energy efficiency in grinding processes. New pulverizing equipment will be developed to minimize material loss and contamination.

As the demand for lithium-ion batteries grows, especially for electric vehicles and renewable energy storage, improving LiFePO₄ processing technology will become more critical. This will drive advancements in ultrafine pulverization.

Conclusion

Ultrafine pulverizer technology plays a pivotal role in enhancing the performance of Lithium Iron Phosphate. LiFePO₄ is an essential material in energy storage and lithium-ion batteries. By improving particle size control and material uniformity, ultrafine grinding enhances the electrochemical properties of LiFePO₄.

This makes it more suitable for high-performance applications. As the technology advances, it will offer further benefits in efficiency, sustainability, and cost-effectiveness. This will contribute to the growth of the energy storage and electric vehicle industries.

The integration of EPIC ultrafine pulverizers with LiFePO₄ processing holds great promise. It will support the future of clean energy storage solutions.