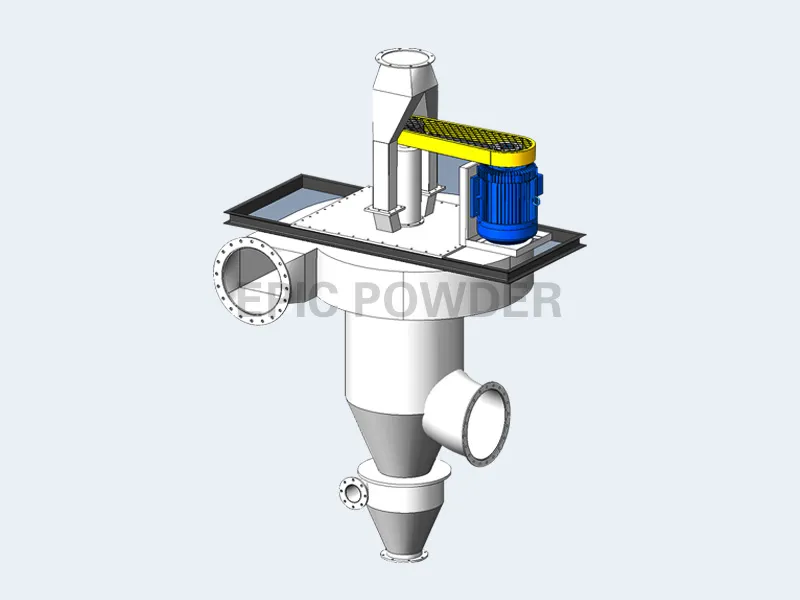

Bộ tách khí

- Năng suất nghiền mịn cao và khả năng nghiền mịn tối đa, với một bánh xe phân loại duy nhất

- Bột siêu mịn trong phạm vi d97 = 3 µm đến d97 = 45 µm

- Phân loại bánh xe được hỗ trợ trong vòng bi ở cả hai bên

- Cửa thoát vật liệu mịn ngập nước kép

- Nguồn cung cấp vật liệu thức ăn được tối ưu hóa trực tiếp đến bánh xe phân loại

- Thiết kế nhỏ gọn và tiện dụng

Nguyên lý hoạt động

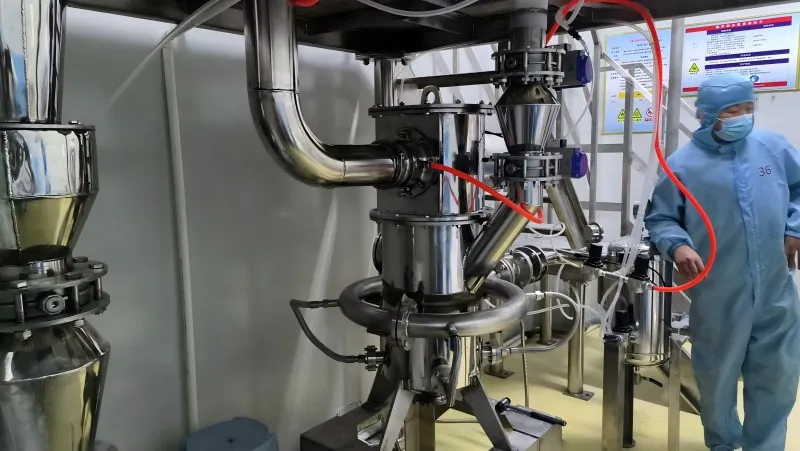

Cổng nạp liệu của máy phân loại nằm ở phía trên cùng của máy phân loại. Nguyên liệu nạp vào máy phân loại từ cửa vào phía trên dưới tác động của trọng lực, sau đó rơi vào đĩa phân tán ly tâm của bánh xe phân loại. Vật liệu sẽ được phân tán đều, phân tán đến vòng chắn và xuống khu vực phân loại. Không khí phân loại đi vào vỏ cuộn, đi qua các cánh dẫn hướng và vào bên trong bánh xe phân loại. Bột mịn được luồng không khí mang vào bánh xe phân loại, sau đó đi vào bộ thu lốc xoáy hoặc bộ thu bụi cùng với luồng không khí, trong khi bột thô sẽ bị lực ly tâm của bánh xe phân loại đẩy ra và rơi vào thân dưới của máy phân loại.

Tính năng và lợi ích

- Thiết kế cấu trúc phân cấp độc đáo, áp suất thấp, tiêu thụ năng lượng thấp.

- Rất tốt cho việc cắt đỉnh của các sản phẩm siêu mịn và các sản phẩm trung bình-mịn.

- Có thể áp dụng cho nhiều kích thước hạt, hạt thô nhất có thể đạt tới 200 micron.

- Có nhiều model khác nhau để đáp ứng các sản lượng khác nhau và công suất cấp liệu của model lớn nhất có thể đạt tới 800 tấn/giờ.

- Thiết kế chống mài mòn, có thể xử lý các sản phẩm dạng bột có độ cứng cực cao.

- Thiết kế lưu thông không khí bên trong có thể giảm đầu tư và tiết kiệm diện tích sàn.

- Có thể kết hợp với máy nghiền bi để tạo thành hệ thống sản xuất tuần hoàn khép kín dùng để nghiền nhiều loại vật liệu khác nhau.

Thông số kỹ thuật

Sản phẩm liên quan

Các trường hợp dự án

Bài viết liên quan

Gửi tin nhắn cho chúng tôi

ĐIỆN THOẠI

+86 15762272120 Thứ Hai đến Thứ Sáu 08:00 sáng – 6:00 chiều

VỊ TRÍ

KHÔNG. 369, Đường S209, Huanxiu, Thành phố Thanh Đảo, 266201, Tỉnh Sơn Đông, TRUNG QUỐC